When choosing new cabinets for your kitchen or bathroom, it’s easy to focus on the color, style, or hardware. But what you don’t see—the construction and materials—often matters even more. The strength, longevity, and overall quality of your cabinetry depend on how it’s built and what it’s built from.

Understanding cabinetry construction terms helps homeowners compare options with confidence. In this guide, we’ll explain the most common terms so you can see what’s really behind the doors.

Cabinet Box Construction

The cabinet box (sometimes called the carcass) is the main structure that supports your drawers, shelves, and doors. Several key construction methods are used:

- Framed Construction: A wooden frame is attached to the front of the cabinet box. Doors and drawers are mounted to this frame, making the cabinet sturdier. Framed cabinets are common in traditional American kitchens.

- Frameless Construction: Also known as “European-style,” frameless cabinets skip the face frame. Doors and drawers mount directly to the box, offering a modern look and slightly more interior space.

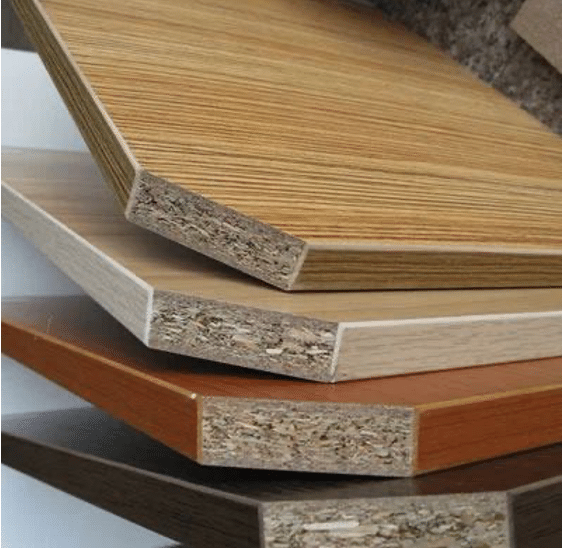

Common Cabinet Materials

Plywood

Plywood is considered one of the best cabinet materials. It’s made of thin layers of wood veneer glued together, with each layer’s grain running perpendicular to the next for strength. Plywood cabinets are durable, resist warping, and handle moisture better than many alternatives.

Medium-Density Fiberboard (MDF)

MDF is an engineered wood product made from wood fibers and resin. It’s smooth, stable, and excellent for painted finishes. Many cabinet doors, especially shaker styles, are built from MDF because it resists cracking around joints. However, MDF is heavier and less water-resistant than plywood.

Particleboard

Particleboard is made of wood chips and resin pressed together. It’s a budget-friendly option, but it’s less durable than plywood or MDF. Many ready-to-assemble (RTA) cabinets use particleboard for interior components. With proper sealing and care, it can still perform well in many kitchens.

Solid Wood

Solid wood offers unmatched natural beauty and strength. Hardwoods like maple, oak, cherry, and hickory are popular for doors, drawer fronts, and face frames. Because wood expands and contracts with humidity, it’s less common for entire cabinet boxes but remains a premium choice for visible parts.

Veneer

A veneer is a thin slice of real wood applied over a base material like plywood or MDF. Veneered cabinets offer the beauty of solid wood at a lower cost while keeping the cabinet lightweight and stable.

Cabinet Joints

How a cabinet is joined together says a lot about its durability.

- Dovetail Joint: Interlocking cuts that fit together like puzzle pieces, often used in drawer boxes. Strong and long-lasting.

- Mortise and Tenon: A classic woodworking joint where a “tenon” fits snugly into a matching hole (mortise). Adds strength to frames.

- Butt Joint: Two pieces simply glued or nailed together. Common in lower-cost cabinets but less durable over time.

Drawer Construction

Drawers take daily abuse, so quality matters.

- Dovetail Drawer Boxes: The gold standard. These feature interlocking joints at the corners, making them sturdy.

- Stapled or Glued Drawer Boxes: More affordable but less durable.

- Full-Extension Glides: Allow drawers to pull out completely, giving access to the entire space.

- Soft-Close Mechanism: Prevents drawers from slamming shut, protecting both the drawer and the contents inside.

Cabinet Finishes

Finishes not only define the look of your cabinets but also protect the material underneath.

- Paint: Offers a smooth, colorful finish. Works well on MDF or hardwood.

- Stain: Enhances the natural grain of wood, often used on oak, cherry, or maple.

- Laminate: A synthetic surface applied to particleboard or MDF. Affordable and durable, available in countless colors.

- Thermofoil: A vinyl coating applied to MDF under heat. It creates a seamless look but can peel if exposed to excessive heat.

Why Materials and Construction Matter

Choosing the right combination of materials and construction methods impacts:

- Durability: Will your cabinets last decades or need replacing sooner?

- Maintenance: Some finishes resist scratches and stains better than others.

- Budget: Materials like solid wood increase cost, while particleboard lowers it.

- Style: A painted shaker door looks different on MDF than on solid maple.

At Cabinet Depot, we help customers balance budget, performance, and design so you don’t have to compromise.

Let Cabinet Depot Guide You

Cabinet construction and materials may not be the most glamorous part of a remodel, but they are the foundation of lasting quality. By understanding the differences between plywood, MDF, particleboard, and other options—as well as how your cabinets are joined and finished—you’ll be better equipped to choose cabinetry that suits your style, lifestyle, and budget.

Whether you’re building a new kitchen or upgrading your bathroom, Cabinet Depot offers a wide selection of cabinets backed by expert guidance. We’ll walk you through every step, from construction details to final installation, ensuring your remodel is built to last.

Visit Cabinet Depot today to explore our cabinet selection and speak with our experienced team. We’ll help you compare materials, finishes, and construction options to design cabinetry that fits your home perfectly.